為何要研磨?

一般在精密工業或半導體業裡,許多公司都為了節省成本而忽略了平面研磨這一道最後的精密製程。常常以銑床加工(CNC)為最後一道製程,在本人的經驗裡CNC加工真的是無所不能可為超強工作母機。但再如何強的工作母機都有優缺點,所以必須依賴其他工作母機來互相彌補其優缺點!

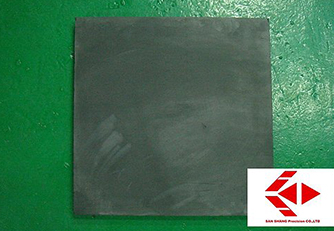

如下圖 此為石墨板 其前段製程為銑床加工 本人特在此板件畫上黃線 來探討其銑床加工的缺點

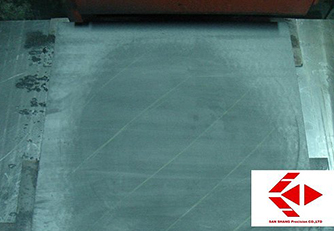

由圖一當中原本其石墨板看似平整但一經過平面研磨後可發現此圖二之石墨板中間為凹陷。此石墨板為石英用途之基板,如一個基礎基板如此,其所生產出來的精密石英類產品必定有誤差,但往往產品出貨前如QC沒盡到責任,則此批產品必定被打回,但這不能完完全全責怪QC,應該再往回推論哪一道製程出錯!

此京華石英科技有限公司專為台積電、聯電生產石英類產品 ,其貴公司非常注重其產品,所以將一件看似無此重要性的基板件,送給敝公司再做平面研磨加工以確保其貴公司產品NG率降低,由此可知平面研磨加工的重要性!

資料來源:三上精密有限公司

轉載頁面:tw.myblog.yahoo.com/kent-73118/article

San Shang Precision Alliance Partner to pursue greater perfection.

Why Polishing?

Graphite plate is a placode used in the fundamental manufacturing of quartz. The first diagram is an original piece of graphite plate that appears to be flawless. The polished material in the second diagram manifests the unsmooth surface as drawn within the yellow lines. This is the factor that causes critical impact on the product quality and the consequences are unpredictable.

Graphite Polishing is the final and most important process for great precision, but usually neglected by most manufacturers for budget controls as it costs more than one Computer Numerical Control (CNC) milling machines to carry out the work.

Jinghwa Quartz Technology has emphasis on the quality of each and every piece of product from the very basics. This is why we collaborate with professionals like San Shang Precision Co., Ltd to provide advanced products to our clients such as Taiwan Semiconductor Manufacturing Co. (TSMC) and the United Microelectronics Corporation (UMC).

Source From: San Shang Precision Co., Ltd

Source Page: tw.myblog.yahoo.com/kent-73118/article